NEC3 : not just for engineering contracts

Introduction

The New Engineering Contract (NEC) was first published in 1993 as a single, but very flexible, form of contract for engineering & construction projects which, amongst other things, stimulated good (project) management between the parties to a contract. Today, in its third edition, the NEC3 family of contracts is a proven form and now offers the same benefits to project managers from almost any sector, which includes those in Information Technology.

This article briefly gives an overview of the NEC3 family of contracts, and how each member of the family achieves the three principal design objectives of the original authors which are:

- Flexibility

- Clarity and Simplicity

- Stimulus to good (project) management.

The NEC3 family of contracts

For completeness, there are four members of the family for use solely on engineering and construction projects. Briefly, these are

- The NEC3 Engineering & Construction Contract (ECC).

- The NEC3 Engineering & Construction Subcontract (ECS), which is backto-back with the main form.

- The NEC3 Engineering & Construction Short Contract (ECSC) for low risk low complexity work. Consequently, as with the other short forms in the family, it does not contain many of the management features of the full ‘long’ contracts. As a result ‘short’ forms are shorter and simpler.

- The NEC3 Engineering & Construction Short Subcontract (ECSS), which is back-to-back with the Short Contract, but can also be used for low risk, low complexity subcontract packages when the main contractor is under the main form.

These are now widely used in the engineering & construction sectors across a wide range of disciplines e.g. water, power, transportation and nuclear.

The NEC3 Professional Services Contract (PSC) has been used widely since it was first published in 1994 and can be used for the delivery of any professional services. While this was originally for engineering design or advice type services, the author knows some clients who use it for all their professional services, which has included, for instance, project management services and lawyers. What appeals to clients is the additional project management rigour and accountability it puts on professionals to deliver their services to time, cost and performance.

The NEC3 Term Services Contract (TSC) was first published when the third edition came out in 2005. Up to then, the Engineering & Construction Contract had been frequently modified for term services : for instance, the author had done one variant which was used by one client for 5 separate contracts : ‘hard’ facilities management for building maintenance and minor improvements; and ‘soft’ facilities management for services such as cleaning; security; reception and cooking services. The TSC could be used for all of these, as well as for IT terms services, although my view is that it would need some minor modifications for use with performance or output specifications.

Under the TSC, the client can specify a secondary option for Task Orders. These would be improvement projects related to the original term service. For example, in an IT outsourcing contract, this could be a systems enhancement instigated by the client and not in the original Service Information document. This has two main advantages:

- it avoids the need to negotiate and put in place an additional contract for the improvement, with the contract terms already agreed and in place when the original contract was let (and the client has much of the commercial power !)

- it brings in many of the features of the other project based contracts in order to effectively project manage and deliver the Task.

In the same way that there is ‘short form’ for simple engineering & construction contracts, there is also a NEC3 Term Services Short Contract (TSSC) for use with contracts to provide straightforward low risk services.

Newly published in early February 2010, is the NEC3 Supply Contract. This can be used for both local and international procurement of high value & / or high risk manufactured goods and for the services directly associated with their supply. This typically means the goods will be wholly or partly be designed and manufactured specifically for the project to the client’s specification, regardless of who is doing the detailed design. Consequently, the Supply Contract has many of the project management features of the other NEC3 long forms.

For the supply of standard commodities, the NEC3 Supply Short Contract was also published in January 2010. This is a fair and even-handed 2 page contract.

The NEC3 Framework Contract, published in 2005 when the third edition of the family came out, can be used for both project based packages of works and services or for call-off type arrangements for commodities. It provides the over-arching framework for a commercial relationship over a period of time, with each package or arrangement being contracted under one of the other members of the family.

Other Aspects of Flexibility.

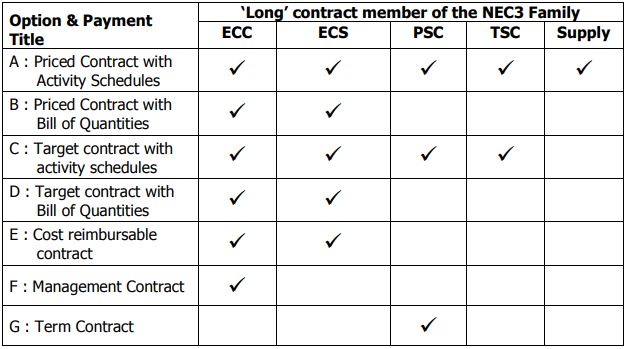

With the exception of the Supply Contract, all the ‘long’ forms of contract have main and secondary options. The main options govern how the contractor is paid and hence the primary risk allocation. For instance:

- main option A is a fixed priced activity schedule arrangement where the supplier (be they contractor, consultant, terms services provider or manufacturer) is paid a fixed price as per their offer (assuming no change). Consequently, the supplier is taking the majority of the risk;

- main option C is a target cost arrangement where the supplier and client share pain / gain within the target price in contractually specified proportions. It is therefore suitable for use where both parties have influence over the risks included within the target and both parties gain by working together to manage them.

- main option E is cost plus percentage fee arrangement, where the supplier is typically either unable to realistically price or bear the risk. I.e. the Client is taking most of the risk.

The range of main options within the family is summarised in the table below.

Table 1 : Contract Strategy / Payment options within the NEC3 Family of Contracts

In addition, there are 20+ secondary options across the family, which allow the client to fine tune the conditions of contract to their requirements without hiring expensive lawyers to (re)draft parts of it (which in itself creates a risk to the project of ambiguity and uncertainty in the contract documents). The numbering and wording of these secondary options is virtually identical across the family.

While it is not possible to explain each secondary option in this article, I will mention option X12 : the partnering option. Use of this option can effectively create an alliance, whether strategic or project based, whereby joint governance, joint working arrangements, performance measurement and incentive arrangements are created between the parties to a programme or project.

On a strategic programme based relationship, this can drive continuous improvement over time.

On an individual project, a joint contractual arrangement can be created where all major parties commercial interests are aligned to the success of the project as opposed to just their individual contracts.

Clarity and Simplicity

It is beyond the scope of this article to go into too much detail of how this is achieved, but briefly:

- There is a common structure, logical information flow and, wherever possible, terminology across the whole family, so once there is basic familiarity, it is much easier to find what you are looking for whatever member of the family you are using. Additionally, it means that common management and administration system can be used whatever member of the family is used. This has major benefits on complex multi-disciplinary projects!

- It has an extremely succinct (some have said ‘terse’) style. Consequently, it is much shorter than traditional contracts, so there is less for participants to know and understand;

- It is written in plain English so, with the exception of many lawyers, the vast majority of people find it is easier to understand their own and others’ rights, obligations, remedies etc.

All this means that, with a little bit of training, it is far more likely that people follow and comply with the contract, as opposed to put it in the drawer and hope everything turns out alright. The latter approach is fine when a project encounters few difficulties, but, in my experience, almost always causes bigger problems downstream in trying to resolve ownership and quantum of the difficulties.

Stimulus to Good (project) Management

The NEC3 family of contracts aims to promote good project management between the parties to a contract or even project. This is in contrast to more traditional contracts where the emphasis is more on administration, with good project management being something you do over and above that of the contract requirements. To illustrate the difference, when a client’s risk occurs (a compensation event in NEC speak) :

- Good administration would be where you note it and agree that it is client’s risk, record extra hours spent and then work out the time and cost entitlement based on those agreed records.

- Under the NEC, good management could mean you have early warning of this change, you decide how you will manage it to minimise the impact on your objectives and ideally pre-assess and agree any additional time and cost entitlement.

Before the original Panel wrote any of the NEC, they wrote out a performance specification in terms of what behavioural and management effects they wanted each set of clauses to encourage. Consequently, good project management is embedded throughout the contract. That said, the main project management features present in all of the ‘long’ forms are:

- There is a named individual who has management powers allocated to him or her under the contract. E.g. in the ECC, it is the Project Manager; in the TSC, the Service Manager; in the Supply Contract, the Supply Manager. Consequently, he or she can be held much more accountable for delivery.

- A detailed and regularly updated programme, which shows the contributions of each party.

- A active and updated Risk Register, with actions against each risk.

- An early warning procedure where both parties have an obligation to notify the other of emerging threats, with each being able to call a meeting to “decide upon actions and who will take them in accordance with the contract”. These threats and actions are then entered into the Risk Register.

- Clearer “Yes” or “No” definitions of compensation events (client risks), so that the parties can much more rapidly agree who’s risk it is, and the party who owns the risk can then lead the management of it.

- More explicit, less subjective criteria for the evaluation of these compensation events based upon the current contractual programme. This reduces argument over the time and cost effects of client risks, allowing participants to focus on the management of the actual risk, as opposed to the management of the related ‘claim’.

- Explicit maximum timescales for all actions, as opposed to the typical “within a reasonable time” of traditional contracts.

Many of these features have incentives for the supplier to perform. For instance, until the supplier provides a programme which contains the information required, a quarter of money owed can be withheld. This provides a big incentive to supply a programme!

If the client or their representative does not do or provide something which they contractually should do by the time they should do, then it is normally quite clearly a compensation event with the time and cost effects more evident. Consequently, it provides an incentive for the client side to perform.

From my early research back in the 90’s on engineering and construction contracts, the most evident effect of using the NEC was the time to agree the final account: on 27 out of the 30 contracts I looked at it was agreed within 3 months of project delivery when the industry norm was far longer (6 months to a 3 years being common).

However, on some of the projects which had experienced significant change, the Project Managers were adamant that on a traditional form of contract, not only would it have taken far longer, with far more expense to agree the final account, it would also have taken far longer with far more expense to actually deliver the project. The reason given, in broad terms, was that the NEC gave them the power to manage their contracts, whereas traditional contracts did not.

Wouldn’t you, as a Project Manager in any discipline, like to be in this position ?

Summary

The NEC3 family of contracts can now be used, with little modification, for virtually all types of procurement ranging from that of simple commodities to major projects and outsourcing arrangements.

The NEC3 family of contracts does have its critics and is certainly not perfect. However, as well as putting into practice its design principles of ‘Flexibility’ and ‘Clarity & Simplicity’, from a project manager’s perspective its main advantage is the ‘Stimulus to Good Management’. This allows Project Managers to really project manage contracts, as opposed to just administrate them and hope everything turns out alright. Consequently, it significantly enhances (but does not guarantee) the likelihood of projects being delivered to their time, cost and performance objectives.